Nykøbing Sugar Silo

A new prestressed concrete silo with heated outer walls with a capacity of 60,000 tons of sugar constructed in slipforming

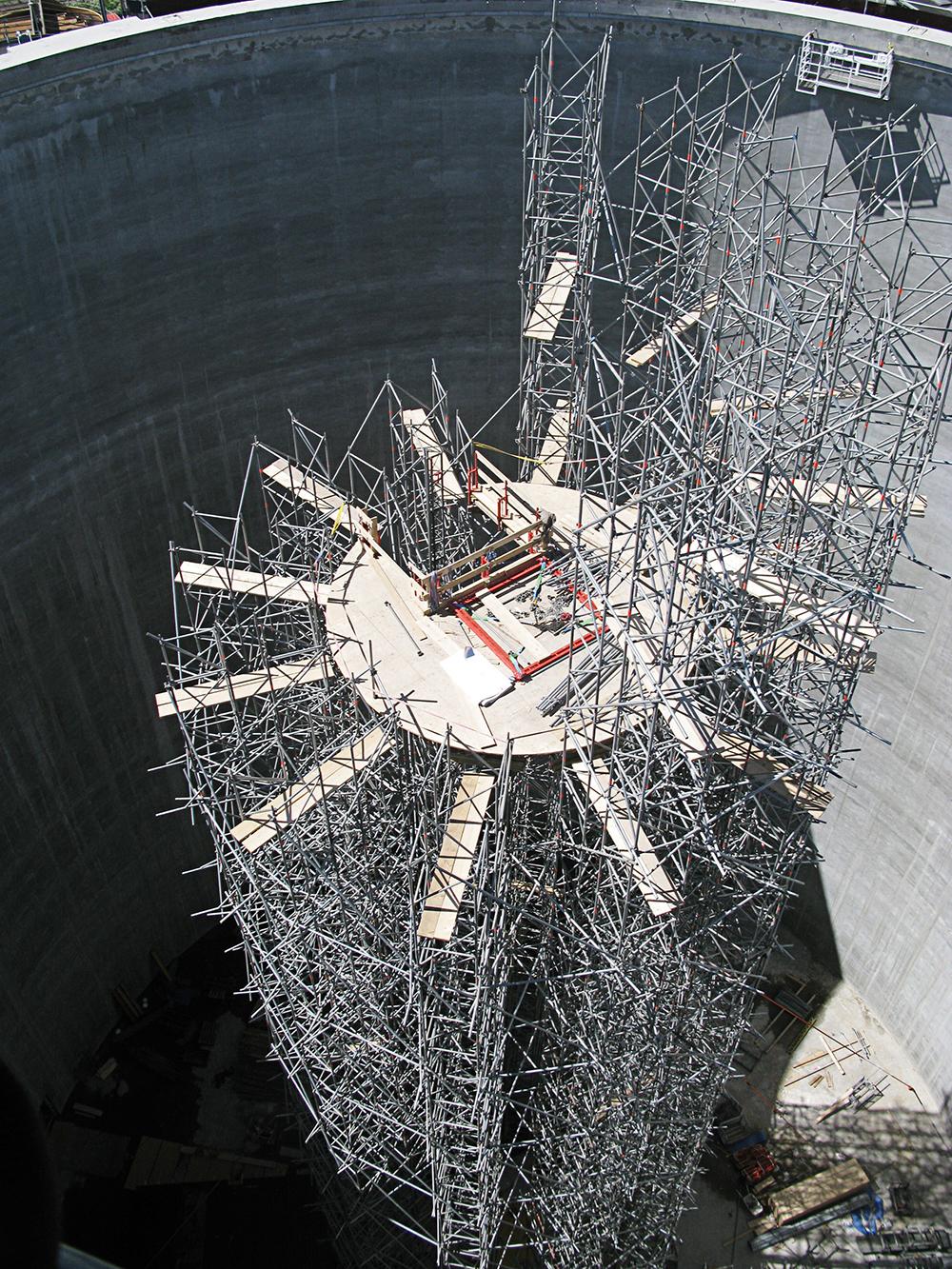

The Danish island of Falster constitutes the centre of the Nordic sugar industry. On the existing company site, a silo was built with a capacity of 60,000 tons of granulated sugar. After a planning phase lasting only four months, the structure then took nine months to build. The silo stands on shallow foundations in the form of a ground slab and has a diameter of 45 metres. The total height is 60 metres, whereby the prestressed concrete structure was constructed using a slipform method. The conical roof is a wooden structure with a compression and tensioning ring and rests unrestrained on the silo wall. Steel was used to create the dome of the silo and the connecting bridges. The sugar silo has complete thermal insulation.

In addition to the required complex building technology, scheduling was tight, too. Close coordination was required between the different trades and the plant and equipment suppliers from a very early date.

| Owner | Nordic Sugar A/S |

| Client | Heitkamp Ingenieur- und Kraftwerksbau GmbH |

| Project data | Height: 60 metres, Diameter: 45 metres |

| Location | Nykøbing, Denmark |

| Completion | 2010 |

Our services

WTM Engineers provided the following services for the Nykøbing sugar silo project:

- Project design

- Structural design

Should you have any questions or require further information on one of our projects?

then simply send an email to: info@wtm-engineers.de